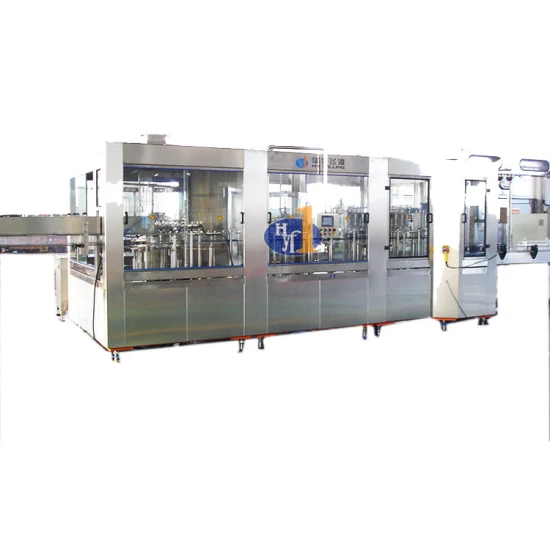

Автоматическая машина для наполнения и укупорки жестяных банок, продуктов питания, напитков, косметики, промышленности.

Размер упаковки на единицу продукции 180,00 см * 200,00 см * 180,00 см Вес брутто на единицу продукции 200 000 кг Автома

Отправьте запросОПИСАНИЕ

Базовая информация

| Модель №. | СДФГИТЖ |

| Индивидуальные | Индивидуальные |

| Сертификация | ISO9001, КС, ГС, ТЮВ, ГБ, ГМП |

| Панцер-Марериал | Металлтанк |

| Введите | Танк-контейнер |

| Объекты хранения | Твердые, жидкие, газообразные, соус |

| Основные компоненты | Двигатель, сосуд под давлением, насос, ПЛК, коробка передач, подшипник |

| Транспортный пакет | Деревянная коробка |

| Спецификация | Покрыты импортной антистатической пленкой, армированы. |

| товарный знак | В дер Шоу |

| Источник | Шанхай |

| HS-код | 8422301090 |

| Производственная мощность | 10000 |

Упаковка и доставка

Размер упаковки на единицу товара: 180,00 см * 200,00 см * 180,00 см. Общий вес единицы продукции: 200 000 кг.Описание продукта

Автоматическая машина для наполнения и укупорки жестяных банок, продуктов питания, напитков, косметики, промышленности.

| Модель | СДФ12-4 | СДФ18-4 | СДФ24-6 | СДФ32-6 |

| Количество запечатанных головок | 4 | 4 | 6 | 6 |

| Количество заправочных головок | 12 | 18 | 24 | 32 |

| Производственная мощность | 30-180 доза/мин | 30-250 доза/мин | 30-300 доза/мин | 30-400 доза/мин |

| Применимая высота резервуара | 39-160 мм | 39-160 мм | 39-160 мм | 39-160 мм |

| Применимый диаметр резервуара | Φ52,5-99 мм | Φ52,5-99 мм | Φ52,5-99 мм | Φ52,5-99 мм |

| Производительность двигателя | 5,5 кВт | 5,5 кВт | 7,5 кВт | 7,5 кВт |

| Масса | 3100 кг | 3800 кг | 4400 кг | 5500 кг |

| Размеры | 2700*1400*1900 мм | 3050*1750*1900 мм | 2675*1775*1900 мм | 3675*2530*1900 мм |

Our service:Pre-sale: Accept your inquiries and organize special technical seminars to discuss customer equipment requirements. Provide you with a detailed "equipment plan", including:1. Equipment samples;2. The latest technology and technology of related equipment at home and abroad, and the comparison of the advantages and disadvantages of products of related manufacturers;3. GMP process design, plant water and electricity layout;4. Process design of mechanical equipment;5. Related product configuration, spare parts, packaging and after-sales service;6. Determine the equipment and quote item by item.On sale:1. Keep in touch with you at all times, invite customers to visit the company, and supervise production equipment;2. Prepare the equipment manual, file card and tracking card and other related software, and accept your acceptance at any time;3. Regularly report the production progress of the equipment to the customer.After-sales (operate according to the international standard after-sales service)1. One-year warranty, lifetime service, 24-hour after-sales service website, hotline and fax will be opened for you, and domestic customers will basically arrive at the designated location within 24-72 hours;2. The spare parts inventory is fully stocked for a long time, and the wearing parts, consumable parts and important accessories are guaranteed to respond to customers in the first time;3. Regularly return visits to each customer, once a year, and record the equipment file records.Our company's advantages: 1. The practicability of the equipment: The single machine designed and manufactured by Shouda Company has reliable quality, long service life, low failure rate and convenient maintenance. It can run for more than three to five years without failure under normal use. 2. The operability of the equipment: It is easy to operate, easy to learn and master, suitable for people with different educational levels. At the same time, the equipment is highly standardized and has a strong matching ability, which can easily and quickly replace various parts and components of different specifications. 3. Appearance of the equipment: The appearance design of the equipment is beautiful and generous, in line with ergonomic principles. No matter in terms of material, shape, color, or size ratio, we strive to be more humanized design, so that the appearance and internal quality of the equipment and mechanical performance. , achieve the most perfect unity. 4. Advanced equipment:A. The equipment realizes automatic unmanned operation from automatic bottle unscrambling, bottle washing, filling, sealing, capping, labeling, unpacking, packing, box packaging and other processes.B. Successfully solve the instant foaming, dripping and filling accuracy of filling.C. Successfully solve bottle mouth small-diameter filling and adopt vacuum filling method.D. Successfully developed leading technology in the industry HCF-134A filling machine.E. Adopt import high-quality filling pump.F. The magnetic capping method is adopted, which does not damage the cap and does not loosen.G. Successfully solve the problems of bottle feeding and out of the bottle, broken bottles and bottle pouring of special-shaped bottles.

Сопутствующие товары

-

![Автоматическая линия по производству пасты из томатного соуса и варенья чили для машины для наполнения, укупорки и укупорки этикетировочной машины]()

Автоматическая линия по производству пасты из томатного соуса и варенья чили для машины для наполнения, укупорки и укупорки этикетировочной машины

-

![Высококачественная автоматическая машина для наполнения бутылок жидким маслом и кремом с линией маркировки крышек]()

Высококачественная автоматическая машина для наполнения бутылок жидким маслом и кремом с линией маркировки крышек

-

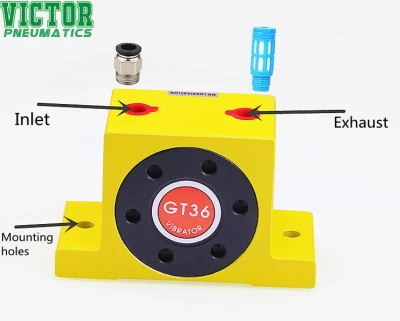

![Findeva Vibrators Gt Пневматический турбинный вибратор, зубчатый вибратор, пулевый вибратор]()

Findeva Vibrators Gt Пневматический турбинный вибратор, зубчатый вибратор, пулевый вибратор

-

![Полностью автоматическая и высокопроизводительная машина для наполнения твердых капсул.]()

Полностью автоматическая и высокопроизводительная машина для наполнения твердых капсул.